| You are here: Technology - Quality Assurance |

|---|

Quality & Service

CCE's customers have a common perspective on doing business with us. They expect CCE to continuously provide them with on time delivery of quality parts to exacting specifications throughout the world. Customers expect that CCE will proactively determine what’s necessary in the future to meet their worldwide needs in product, delivery, and cost --all with the "Right Quality".

Our customers also regularly recognize that our quality efforts exceed their expectations and most often that translates to a preference for annual business contracts—over 80% of our business is done this way.

CCE believe that Continuous Quality Improvement is necessary to sustain mutually rewarding business relationships with our customers on a long term basis. You will find the specifics of our quality programs in the following sectors listed in this section.

|

|

|

|---|---|---|

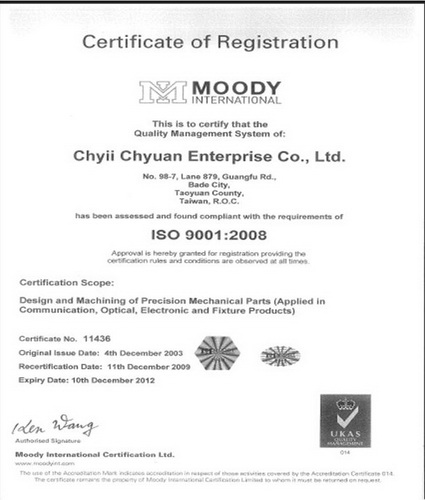

Quality Systems

CCE understand that delivering quality products begin with an organization built to support our customers’ requirements throughout the world. Our ISO 9001/2000 certified systems guarantee that we have the capabilities, methods, and resources to supply defect free products, with on-time delivery, while providing continuous improvements to products and processes, all using Six Sigma tools.

CCE Quality Systems include the procedures by which we define the methods and practices used throughout the company both in Taiwan and China to ensure that quality is built into our products, from prototype machining to full production. Our current Quality Systems meet all ISO 9001/2008 requirements & following additional methods:

In the planning phase of a program:

|

|

|---|---|

In the production phase of a program:

|

|